Performance:

- minimum feature width: 500 microns

- laser beam positioning accuracy: 50 microns

- maximum build volume: 200 mm x 250 mm x 330 mm

- minimum layer thickness: 100 microns

- laser beam scanning beam: maximum 5 m/s

- vertical build speed: minimum 10 mm / hour

The 3D Printer based on selective laser sintering is placed in a specially designed and arranged room.

It is used for production of different structures, at normal and at mili-scale.

Materials:

- PrimePart: Fine polyamid - biocompatible, excellent economics, withstands high mechanical

and thermal load

- PA 2200: Fine polyamid - biocompatible, withstands high mechanical and thermal load

- PA 3200 GF: Glass-filled fine polyamide - hard-wearing, withstands high mechanical and

thermal load

- PrimeCast 101: Polystyrene - for lost patterns, minimal remaining ash content

- PA 2210 FR: Flame-retardant polyamide - contains chemical flame retardant, high mechanical

properties

- PA 2201: Fine polyamid - withstands high mechanical and thermal load

- Alumide: Aluminium-filled polyamid - stiff structures, thermally conductive

- PS 2500: Polystyrene - for lost patterns

Applications:

- models realization (for engineering, architecture, education)

- realization of molds for implants

- realization of molds for automotive industry, rubber industry (envelopes for tyres), plastics

industry, optical industry (special lenses and special mirrors), medicine (prosthetics), museums

(copies of sculptures hat are very important), components for construction of industrial

machines, glass industry, porcelain industry

- realization of fix, mobile or semi-mobile mechanical components for specific applications,

including robotics

- realization of microfluidics structures and circuits (channels of several hundreds of microns

diameter, connected in complex 3D geometries) containing pipes, valves, micropumps (at

milimetric and centimetric scale)

- realization of joining elements (screws, etc.) at milimetric scale

- realization of customized encapsulations for different type of MEMS structures

- realization of MEMS models for testing their concept and working principle

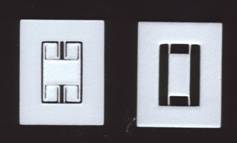

Some examples of structures realized at the 3D Printer based on selective laser sintering

|

|