Results

2017 Design, Fabrication, Characterization and experimental testing of microtweezers with integrated sensors

|

|

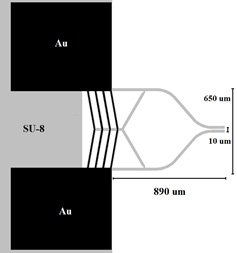

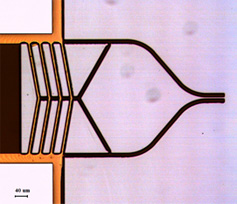

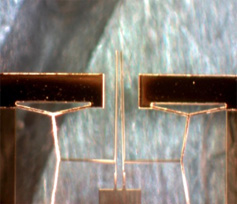

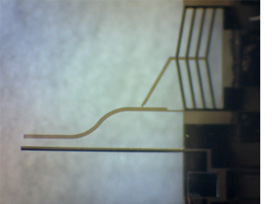

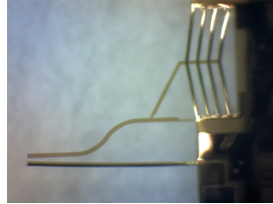

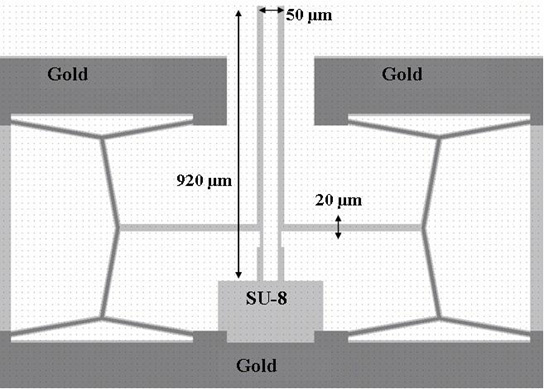

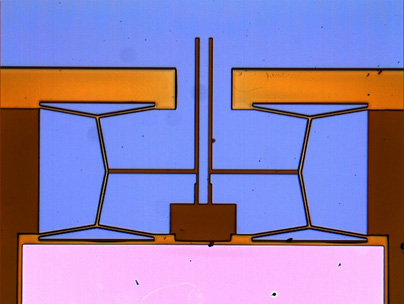

Design of the micro-tweezer fabricated using SU-8/Au; b) Optical image of the fabricated SU-8 and Gold micro-tweezer. |

|

|

|

|

|

|

|

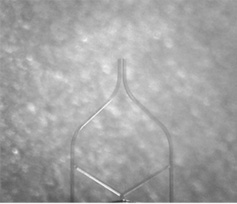

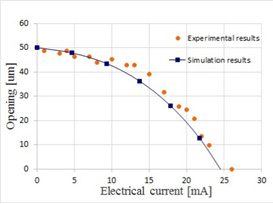

Optical images for the microgrippers in different stages: a) initial position, closed position with an opening of 10 µm; b) opening arms of the microgrippers after actuation; c) initial position, open position with the initial opening of 50 µm; d) actuated microgripper with closed arms; e) Measurements results vs simulation results of the opening of the microgripper tips; |

|

|

|

|

|

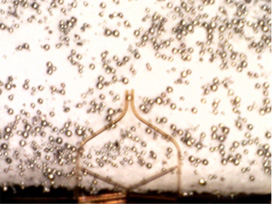

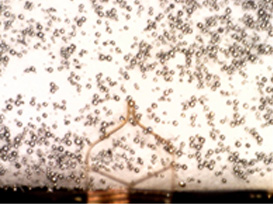

Micromanipulation of different micro-elements: a) gripping a polimeric object; b) positioning and moving the object in another place; c) si d) gripping of micro-elements. |

|

|

|

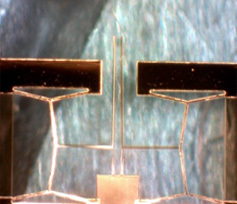

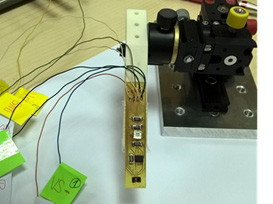

a) Microgrippers with senzors fixed on PCB chip for testing; b) Optical image during testing of piezorezistive sensors for force/displacement. |

|

|

|

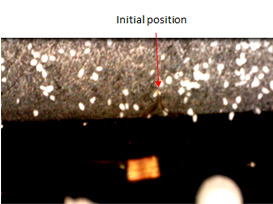

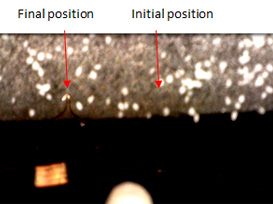

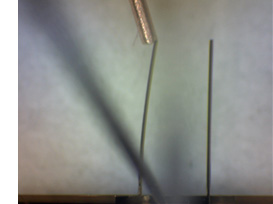

Different actuation stages of the microgrippers integrated with sensors: a) initial opening of the microgrippers fabricated using SU-8/Au; b) closing the arms during electro-thermal actuation. |

|

Design, characterization and fabrication of the MEMS micro-grippers

• Characterization and testing of the materials and the fabrication process for MEMS micro-gripper manufacturing for microrobotic applications

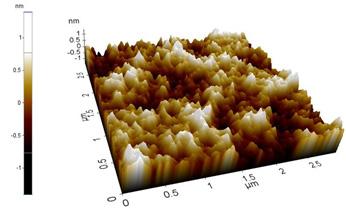

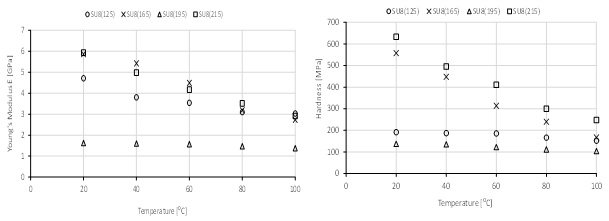

Different conditions were used for the preparation of the SU-8 polymer samples in order to investigate the material properties. We investigated polymeric SU-8 samples prepared on a silicon substrate and hard-baked on a hot plate at different temperatures: 125°C, 165°C, 185°C, 195°C, 205°C and 215°C.

The nanoanalysis of mechanical and tribological properties of polymeric layers at different temperatures using Atomic Force Microscope (AFM) and nanoindentation were realized by the UTC-N and IMT Bucharest partners. A thermal stage was used by the UTC-N to control the temperature of investigated samples in the range of 20°C to 100°C using a Peltier system.

The mechanical properties like hardness and modulus of elasticity and the measurements of their behavior at different temperatures were analyzed.

|

Figure 1 AFM 3D image of the SU8 layer hard-baked at 195°C. |

|

|

Figure 2 Modulus of elasticity vs applied temperature |

Figure 3 Hardness vs applied temperature |

• Design and simulation of MEMS micro-grippers

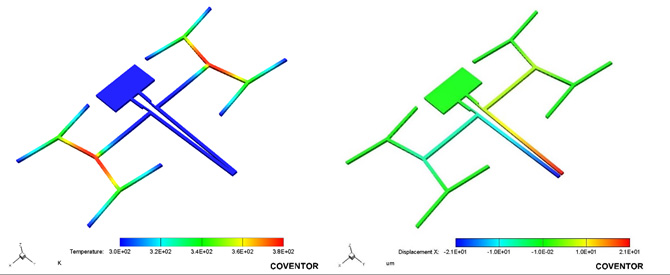

We realized the design and simulations of MEMS micro-grippers based on cascaded chevron V-shaped electro-thermal actuators. The FEM simulations were realized using Coventorware 2014 software tool. Coupled analyses electro-thermo-mechanical were performed in order to analyze the structure behavior.

The micro-grippers were designed using the principle of electrically driven thermal actuation in the normally open operating mode. The micro heaters are embedded in two polymer layers for electrically isolation and to improve thermal efficiency and to reduce out-of-plane displacements.

|

Figure 4 Schematic design of the SU-8 micro-gripper normally open; |

|

a) b) |

• Fabrication of the micro-grippers

The micro-grippers were fabricated using biocompatible materials, such as SU-8 polymer used as structural layer and based on a wet release using the Omnicoat stripper.

|

Figure 6 Optical microscope picture of the fabricated electro-thermal SU-8 and Cr/Au/Cr micro-gripper in IMT Bucharest. |

• Dissemination of the results

2017 Scientific papers and international conference presentations, 2 patent request, 1 topography request:

- M. Al Zandi, R-C. Voicu, R. Muller, C.Wang, Testing and Characterisation of Electrothermal Microgrippers with Embedded Microheaters, Proc. of Symposium on Design, Test, Integration & Packaging of MEMS/MOEMS-DTIP2016, Budapest, pp. 256-260, 2016

-R-C. Voicu, Design, numerical simulation and experimental investigation of an SU-8 microgripper based on the cascaded V-shaped electrothermal actuators, Journal of Physics: Conference Series (JPCS) vol. 757 no. 1, 2016, 012015

- R-C. Voicu, M. Pustan, R. Gavrila, C. Barleanu, R. Muller, Nanomechanical characterization and thermal investigations of SU-8 biocompatible polymer used for MEMS microgrippers fabrication, Book of abstracts 11th International Conference on Surfaces, Coatings and Nanostructured Materials (NANOSMAT2016)

-

R-C. Voicu, C. Tibeica, R. Müller, A. Dinescu, M. Pustan, C. Birleanu, Design, Simulation and Testing of Polymeric Microgrippers with V-shaped Electrothermal Actuators and Encapsulated Heaters, Proc. of IEEE International Semiconductor Conference CAS 2016, 10-12 October Sinaia, 2016, pp. 89-92

- D. Ulieru, X. Vila, A. Topor, “The innovative micromanufacturing solutions of high sensitivity actuators mechanical structure for micro-manipulation”, Innovation Village Section, 24/27 Oct.2016, Book of Abstracts, ALPEXPO, Grenoble, Franta

- M. Al-Zandi, C. Wang, R. Voicu, R. Muller, Measurement and Characterisation of Displacement and Temperature of Polymer Based Electrothermal Microgrippers, Microsystem Technologies, Accepted: 17 January 2017, DOI 10.1007/s00542-017-3298-8

- R-C. Voicu, C. Tibeica, R. Müller, A. Dinescu, M. Pustan, C.Birleanu, SU-8 Microgrippers based on V-shaped Electrothermal Actuators with Implanted Heaters, Romanian Journal of Information Science and Technology (ROMJIST) Vol. 19 no. 3, pp. 269-281, 2016

- M. Pustan, R. Voicu, C. Birleanu, F. Rusu, S. Craciun, Analysis of Temperature Effect on Mechanical and Tribological Properties of SU-8 Photoresist Material, Book of abstracts, 10-th International Conference on Materials Science & Engineering BRAMAT2017, 8 - 11 March 2017

- Rodica-Cristina Voicu, M. Al Zandi, R. Müller, C. Wang, “Nonlinear numerical analysis and experimental testing for an electrothermal SU-8 microgripper with reduced out-of-plane displacement“, IOP Conf. Series: Journal of Physics: Conf. Series 922, (2017) 012006 doi :10.1088/1742-6596/922/1/012006

- Rodica-Cristina Voicu, C. Tibeica, A. Dinescu,“Design, analyses and fabrication of a V-shaped polymeric microgripper with reduced out-of-plane displacement”, book of abstracts, 43rd International Conference on Micro and Nanoengineering – MNE 2017

- R-C. Voicu, C. Tibeica, R. Müller, A. Dinescu, “An SU-8 micro-tweezer based on the chevron electro-thermal actuators with a large in-plane displacement”, Proc. of IEEE International Semiconductor Conference CAS 2017, 11-14 Oct. Sinaia, pp.105-108, 2017

- R-C. Voicu, C. Tibeica, R. Müller, A. Dinescu, “Simulations and experimental testing results for an SU-8 micro-tweezer with in-plane displacement”, send to be published in Romanian Journal of Information Science and Technology, 2017

- C. Tibeica, R. Voicu, “On Simulation of Heat Transfer at Microscale: A Case Study”, Proc. of IEEE International Semiconductor Conference CAS 2017, 11-14 Oct. Sinaia, pp. 217-220, 2017

- R-C. Voicu, C. Tibeica, R. Muller, A. Dinescu, M. Pustan, C. Birleanu, SU-8 Microgrippers based on V-shaped Electrothermal Actuators with Implanted Heaters, Romanian Journal of Information Science and Technology 19 3, 2016, 269-281

- M. Al Zandi, C. Wang, R. Voicu, R. Muller, Measurement and characterisation of displacement and temperature of polymer based electrothermal microgrippers, 31 Jan 2017 in : Microsystem Technologies. p. 1-9, DOI 10.1007/s00542-017-3298-8

- C. Birleanu, M. Pustan, R. Voicu, F. Serdean, V. Merie, Humidity influence on the adhesion of SU-8 polymer from MEMS applications, Book of Abstracts, 13th International Conference on Modern Technologies in Manufacturing, MTeM 2017, 12-13 October, Cluj-Napoca, Romania

- D.Ulieru, Oana-Maria Ulieru, Xavi Vila, A.Topor „Microgrippers as end-effectors with integrated sensors for microrobotic applications ”, Book of Abstracts, Sensor+Test 2017” Conference & Fair, 30 May-1st June, 2017, Nurnberg, Germany.

- D.Ulieru, „Micro and nanosytems, prezent and perspectives of development by innovative concept & technologies applications at SITEX 45”, Book of Abstracts, Conferinta Internationala ICSSCS 2017,13/14 July,2017, Iasi, Romania.

patent request

- patent request OSIM no. A/00360/20.05.2016: „Process of fabrication of electro-thermally actuated MEMS devices with metallic layer embedded in SU-8 polymer used as end-effectors for micromanipulation”, Inventor(s): R. C. Voicu; R. Muller;

- patent request OSIM no. A/00959 /21.11.2017: “DISPOZITIV DE MICRO-PENSETA POLIMERICA INTEGRATA CU SENZOR PIEZOREZISTIV DE FORTA/DEPLASARE PENTRU MICRO-MANIPULARE/ DEVICE OF POLYMERIC MICRO-TWEEZER INTEGRATED WITH PIEZORESITIVE FORCE/DISPLACEMENT SENSOR FOR MICROMANIPULATION”, authors : Rodica-Cristina Voicu, Adrian Dinescu, Raluca Müller

- topography request OSIM no. (Cerere de Topografie de produse semiconductoare) 10/29609/23.11.2017: «Topografie de micro-penseta cu dubla actionare/ Topography of micro-tweezer with double actuation », author: Rodica-Cristina Voicu

Scientific papers and conference presentations, patent request:

- M. Al Zandi, R-C. Voicu, R. Muller, C.Wang, Testing and Characterisation of Electrothermal Microgrippers with Embedded Microheaters, Proc. of Symposium on Design, Test, Integration & Packaging of MEMS/MOEMS-DTIP2016, Budapest, pp. 256-260, 2016

- R-C. Voicu, Design, numerical simulation and experimental investigation of an SU-8 microgripper based on the cascaded V-shaped electrothermal actuators, Journal of Physics: Conference Series (JPCS) vol. 757 no. 1, 2016, 012015

- R-C. Voicu, M. Pustan, R. Gavrila, C. Barleanu, R. Muller, Nanomechanical characterization and thermal investigations of SU-8 biocompatible polymer used for MEMS microgrippers fabrication, Book of abstracts 11th International Conference on Surfaces, Coatings and Nanostructured Materials (NANOSMAT2016)

- R-C. Voicu, C. Tibeica, R. Müller, A. Dinescu, M. Pustan, C. Birleanu, Design, Simulation and Testing of Polymeric Microgrippers with V-shaped Electrothermal Actuators and Encapsulated Heaters, Proc. of IEEE International Semiconductor Conference CAS 2016, 10-12 October Sinaia, 2016, pp. 89-92

- D. Ulieru, X. Vila, A. Topor, “The innovative micromanufacturing solutions of high sensitivity actuators mechanical structure for micro-manipulation”, Innovation Village Section, 24/27 Oct.2016, Book of Abstracts, ALPEXPO, Grenoble, Franta

- M. Al-Zandi, C. Wang, R. Voicu, R. Muller, Measurement and Characterisation of Displacement and Temperature of Polymer Based Electrothermal Microgrippers, Microsystem Technologies, Accepted: 17 January 2017, DOI 10.1007/s00542-017-3298-8

- R-C. Voicu, C. Tibeica, R. Müller, A. Dinescu, M. Pustan, C.Birleanu, SU-8 Microgrippers based on V-shaped Electrothermal Actuators with Implanted Heaters, Romanian Journal of Information Science and Technology (ROMJIST) Vol. 19 no. 3, pp. 269-281, 2016

- M. Pustan, R. Voicu, C. Birleanu, F. Rusu, S. Craciun, Analysis of Temperature Effect on Mechanical and Tribological Properties of SU-8 Photoresist Material, Book of abstracts, 10-th International Conference on Materials Science & Engineering BRAMAT2017, 8 - 11 March 2017

- patent request OSIM nr. A/00360/20.05.2016: „Process of fabrication of electro-thermally actuated mems devices with metallic layer embedded in SU-8 polymer used as end-effectors for micromanipulation”, Inventor(s): R. C. Voicu; R. Muller;