Project objective

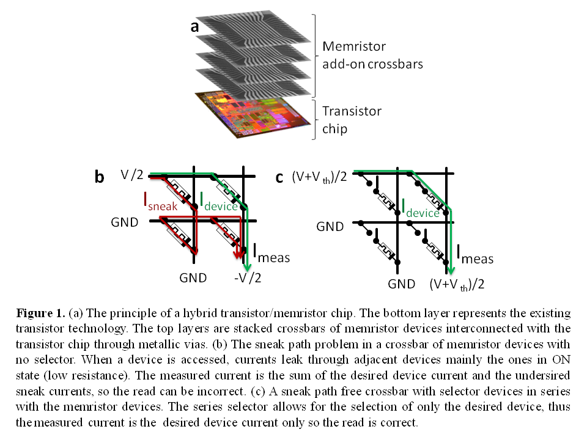

The project proposes the use of NEMS relays as selector devices for memristor crossbars and pursues the simulation, fabrication and characterization of a proof-of-concept crossbar of monolithically integrated memristor/NEMS device.

Project description and overview of the results

The SelectX project was structured in five work packages (WPs). The WP1 developed the active material used for memristor fabrication in other WPs. The WP2 referred to the fabrication of individual memristors and was pursued in parallel with WP3, the simulation and fabrication of two-terminal MEMS selectors. The results from WPs 2 and 3 were combined in WP4 - fabrication of an integrated memristor-MEMS device. The final WP5 was the fabrication of a crossbar of integrated memristor-MEMS devices.

|

|

- WP1.Material development

Substoichiometric titanium dioxide (TiO2-x) was the material of choice due to its good memristive properties. The initial plan was to deposit substoichiometric TiO2-x using reactive sputtering, but it was not successful due to experimental difficulties with the sputtering equipment owned by IMT Bucharest. An alternative method - evaporation from TiO2 pellets in vacuum - was pursued with success, using an e-beam deposition tool at IMT. The deposited material was sub-stoichiometric with high initial conductivity.

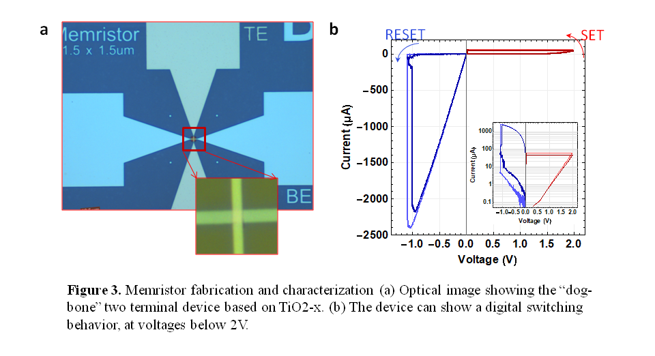

- WP2.Single memristor

Based on the substoichiometric TiO2-x from WP1, memristors as small as 1.5 x 1.5µm^2 (Fig 3a) were fabricated in three photolithography steps using the cleanroom facilities at IMT Bucharest. The device programming was done using a Keithley parameter analyzer, by applying voltage to top electrode and grounding the bottom one. The memristor has low forming (<3V) and switching voltages (~-1.5V for reset and 1.2 - 2V for set) (Fig 3b) and behaves in a reliable digital fashion with an ON/OFF ratio ~ 1000.

|

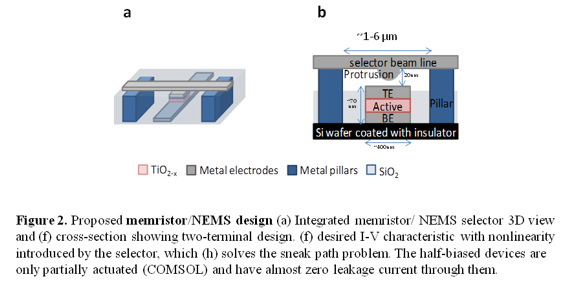

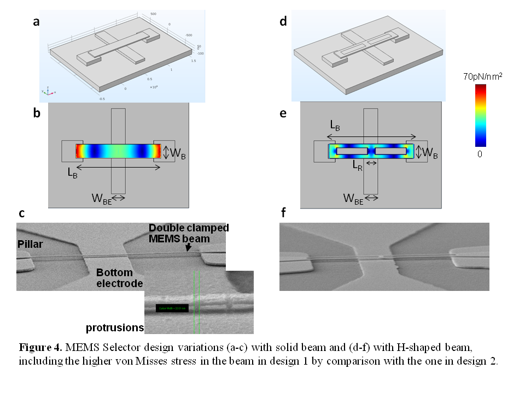

- WP3.Single MEMS selector

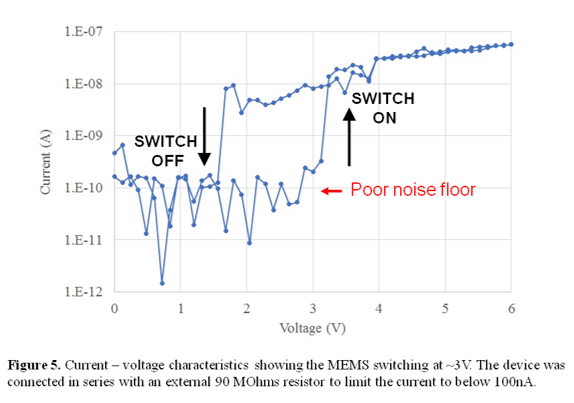

The MEMS selector is the novel concept proposed, so it was extensively investigated in COMSOL simulations and experimental fabrication. MEMS are typically large (~100µm) and have high actuation voltages (>50V), not desirable for a selector. Lee et al. (2013) showed a nanoelectromechanical switch with low actuation voltage (Vth<1V), but its pipe clip structure is prone to stiction. Our design has a metallic beam supported by pillars separated from a fixed bottom electrode by a small air gap. The switch is electrostatically actuated by applying a voltage between the beam line and the bottom electrode. Two beam geometries– solid vs. H-shaped- were simulated in COMSOL (Fig 4). The H-shaped one showed reduced actuation voltage, but slightly higher stress at the corners. For a memristor-compatible fabrication, metal pillars were first patterned to support the beam line. A bottom electrode was patterned in the gaps between the pillars, then the entire structure was covered with a sacrificial SiO2 layer for temporary support of the beam. To ensure that the beam is fabricated on a flat surface, chemical mechanical polishing was done at EPFL during three secondment trips (September 2016, March and September 2017). Devices with protrusions were fabricated to reduce the contact area. Lastly, the SiO2 was removed. The device was tested in series with an external 90MOhms resistor. The current – voltage characteristics (Fig 5) has a sharp transition at ~3V when the switch turns ON, then the series resistor limits the current in the 100nA range. When the voltage drops <1.5V, the beam disconnects and the switch returns to OFF.

|

| |

|

- WP4.Integrated memristor/MEMS selector

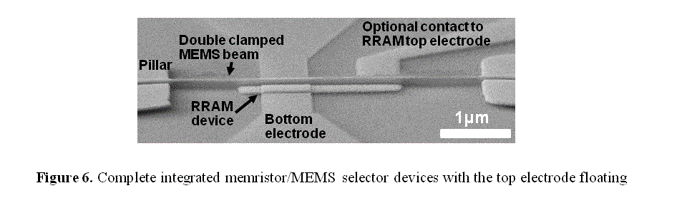

The selector design from WP3 was modified to accommodate the memristor from WP2. After the bottom electrode fabrication, another additional e-beam lithography step is performed to deposit the active layer and top electrode of the memristor device. The integrated device then follows the same steps as the single NEMS selector: SiO2 deposition, planarization, beam patterning and release. The integrated memristor (Fig 6) showed improved non-linearity, but future work will focus on hermetic device encapsulation since the devices were affected by humidity and stiction.

|

- WP5.Crossbar of integrated devices

The results from WP4 were expanded in WP5. With the help of two summer interns, a matrix of such integrated devices was simulated in COMSOL, then a prototype 5x5 crossbar of memristor/MEMS devices (Fig 7) was fabricated using the same basic device design proposed in WP4. This structure, although of modest size, is the first integrated crossbar of memristors and MEMS selectors. The success of this prototype enables much larger arrays that implement artificial neural circuits.

Publications and reports

The dissemination of the results include following peer-reviewed conference papers, oral presentations and posters:

- Paper “NEMS Relay as Integrated Selector Device for Memristor Crossbars” has been accepted for oral presentation at the 17thedition of the International Symposium on RF-MEMS and RF-MICROSYSTEMS (MEMSWAVE 2016)

- Adam G.C., Solot A., Dinescu A., Fernandez-Bolaños M., Ionescu A.M., Müller A. "Exploring the use of a MEMS Relay as an Integrated Selector Device for ReRAM Crossbars", 28th Micromechanics and Microsystems Europe Workshop, Uppsala, Sweden, 2017.

- Adam G.C. "On the Reset Threshold Voltage of ReRAM Devices and its Impact on the Implication Logic Operation", Proceedings of the IEEE International Semiconductor Conference, Sinaia, Romania, 2017.

- Adam G.C., Hoskins B.D., Chakrabarti B., Strukov D.B. "Challenges and progress in three-dimensional stacking of passive analog ReRAM crossbars", poster in International IMEC-Stanford Workshop on Resistive Memories, Leuven, Belgium, 2017.

- Adam G.C., Nili H., Kim J., Hoskins B.D., Kavehei O., Strukov D.B. “Utilizing I-V Non-Linearity and Analog State Variations in ReRAM-Based Security Primitives”, paper + oral presentation in European Solid-State Device Research Conference (ESSDERC), Leuven, Belgium, 2017.

- Adam G.C., Chakrabarti B., Hoskins B.D., Nili H., Strukov D.B. “Fabrication, CMOS Integration and Applications of Non-volatile 3D Metal Oxide Crossbars” keynote presentation for topic Technology at the International Conference on Memristive Materials, Devices & Systems (MEMRISYS) 2017.

- Adam G.C., Chakrabarti B., Nili H., Hoskins B.D. “Digital and Analog Applications of 3D Metal Oxide Crossbars”, poster in “Beyond CMOS: From devices to systems” workshop, Haifa, Israel, 2017.

- Adam G.C., Chrakrabarti B., Nili H., Hoskins B., Lastras-Montaño M.A., Madhavan A., Payvand M., Ghofrani A., Cheng K.-T., Theogarajan L., Strukov D. B. “3D ReRAM Arrays and Crossbars: Fabrication, Characterization and Applications”, paper + oral presentation at IEEE Nano, Pittsburg, USA, 2017.

- Gina gave an invited seminar at IBM Zurich Research Laboratory with the title “Optimizing passive analog ReRAM crossbars for neuromorphic applications” on 18th of September, 2017.

- Gina was invited to give a seminar at NIST Gaithersburg with the title “Tailoring Resistive Switches for Applications in Artificial Intelligence and Beyond” on the 19th of March, 2018.

In the media

- Gina had a 30-min interview at the national Romania radio post, Radio Romania Cultural, on 21st of January, 2017. The interview discussed her research work on neuro-inspired systems and her educational background, including the MSCA-IF grant and several other awards and fellowships she has received. The recording of the interview is available in Romanian at http://radioromaniacultural.ro/azi-radio-romania-cultural-nascut-in-romania/

- Gina was interviewed by the magazine MarketWatch for their August 2017 edition related to her research at IMT Bucharest and her experience of reintegrating in Romania. The article is available in Romanian at http://www.marketwatch.ro/articol/15700/Tinerii_cercetatori_valorosi_atrasi_de_nucleele_stiintifice_de_excelenta_din_Romania

- Gina participated in the Member of the Parliament (MEP) - Scientist program in Brussels on 28-30th of November, 2017

(http://www.europarl.europa.eu/stoa/cms/home/panel_meetings/mepscientist) organized by the European Parliament Science and Technology Options Assessment. This program aims to facilitate better understanding between EU parliament members and the researchers in areas of social importance such as artificial intelligence. Gina has been one out of 17 scientists selected and the only one from Romania.

- Gina was invited on stage at the European Researcher Night in Bucharest on September 29th, 2017 to briefly present her research and her experience of being a scientist and answer questions from middle school and high school students.

|