Results

- SAW on GaN structure fabrication and optimization for temperature sensor application [...]

- SAW devices characterization as temperature sensor in the range -65 ...+120 OC [...]

- Experiments for SAW based temperature sensor

Rezults 2013

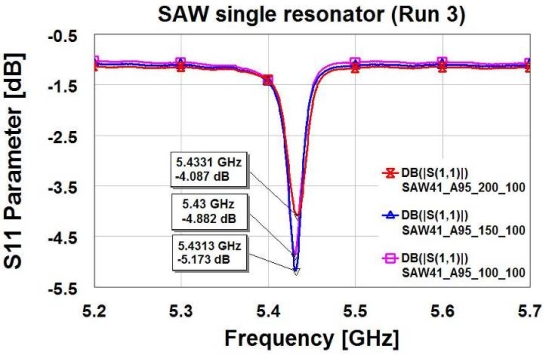

New SAW structures as temperature sensors

In order to optimize the SAW structure, several tests were performed. The length of the fingers was decreased to 100 μm, 50 μm and 20 μm. Also, for each length, the number of fingers was varied: 20, 100, 150, 200. The influence of these two parameters on the resonance frequency and on the quality factor was observed. The best results were obtained for the structure having 150 fingers of 100 μm length. For this structure the resonance frequency is 5.43 GHz and the quality factor is Q = 286 compared to Q = 271 obtained for the structure having 100 fingers of 100 μm length

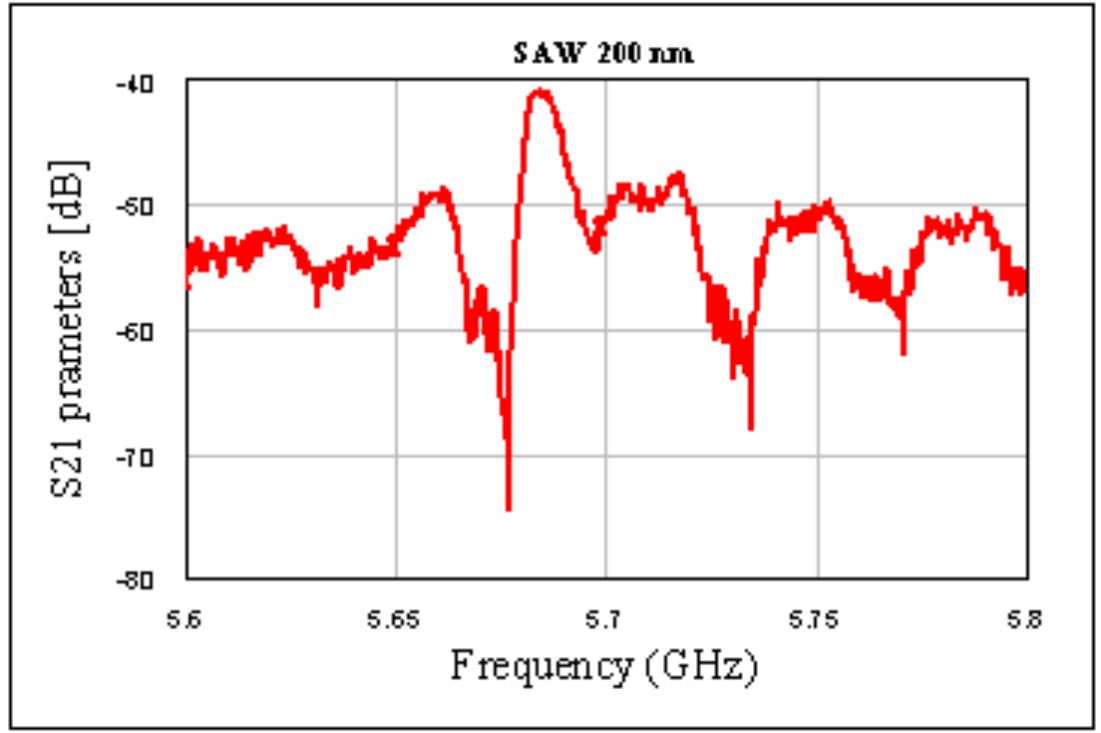

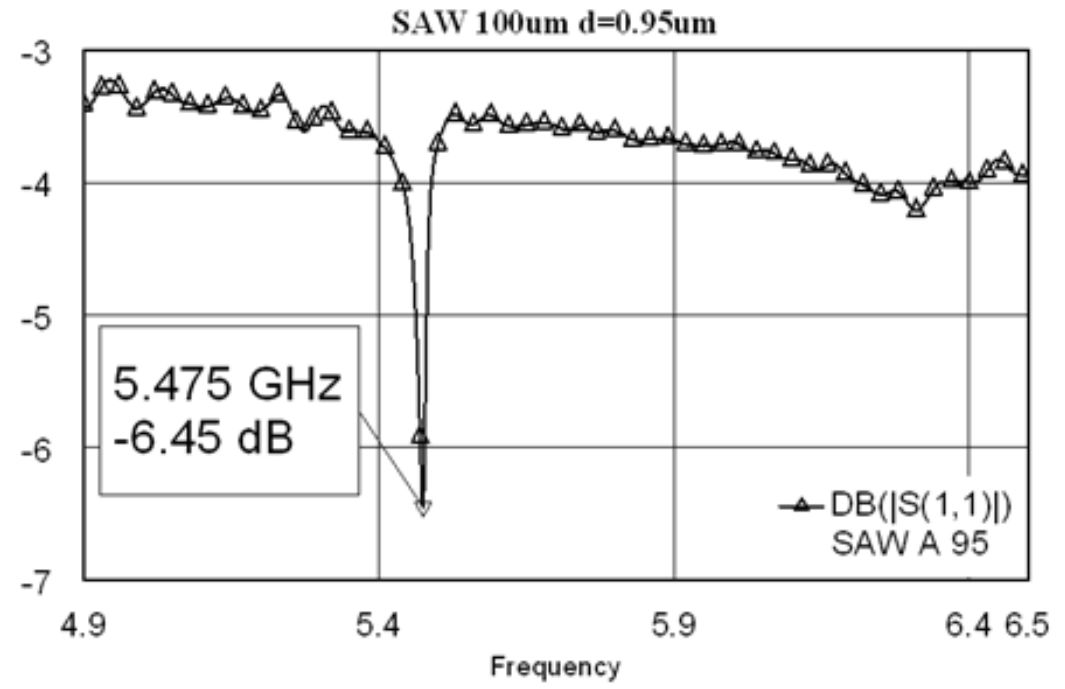

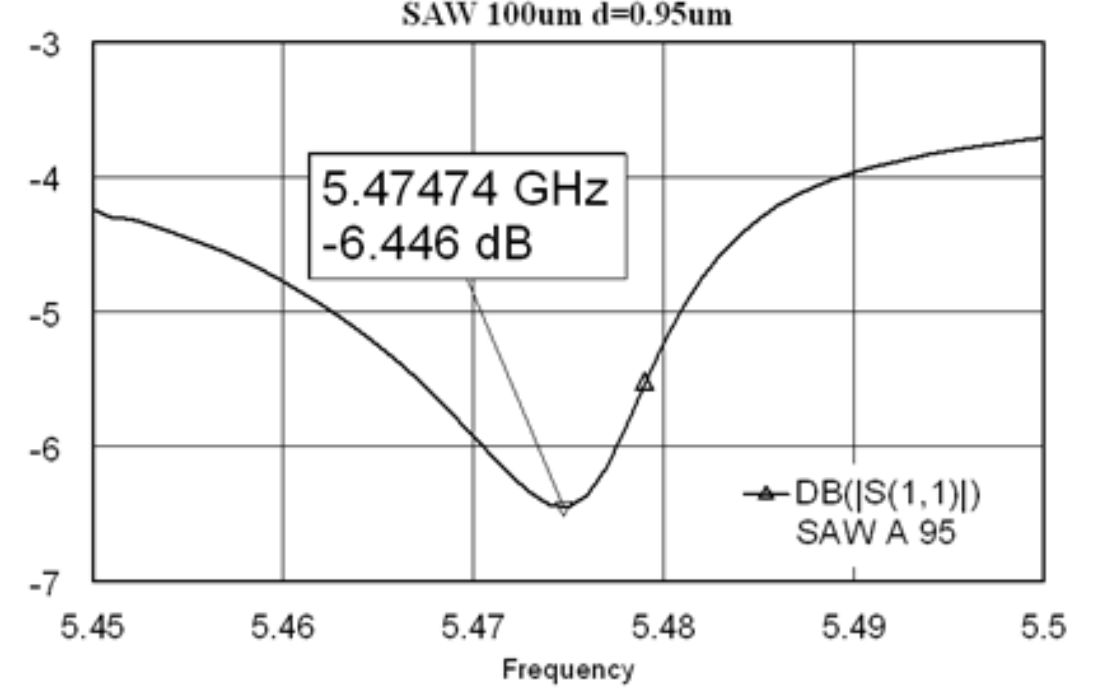

S11“on wafer” characterization for SAW structures

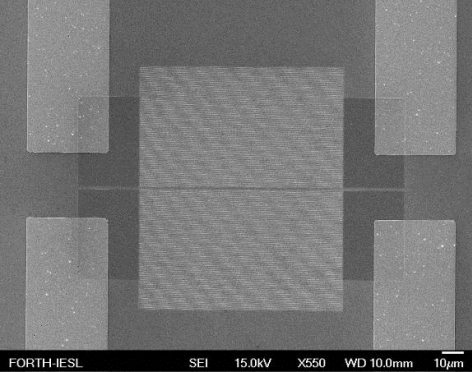

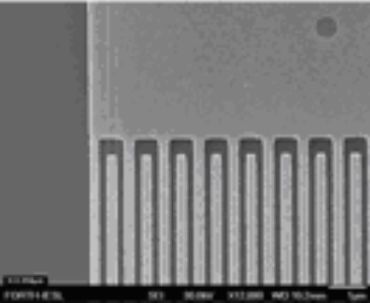

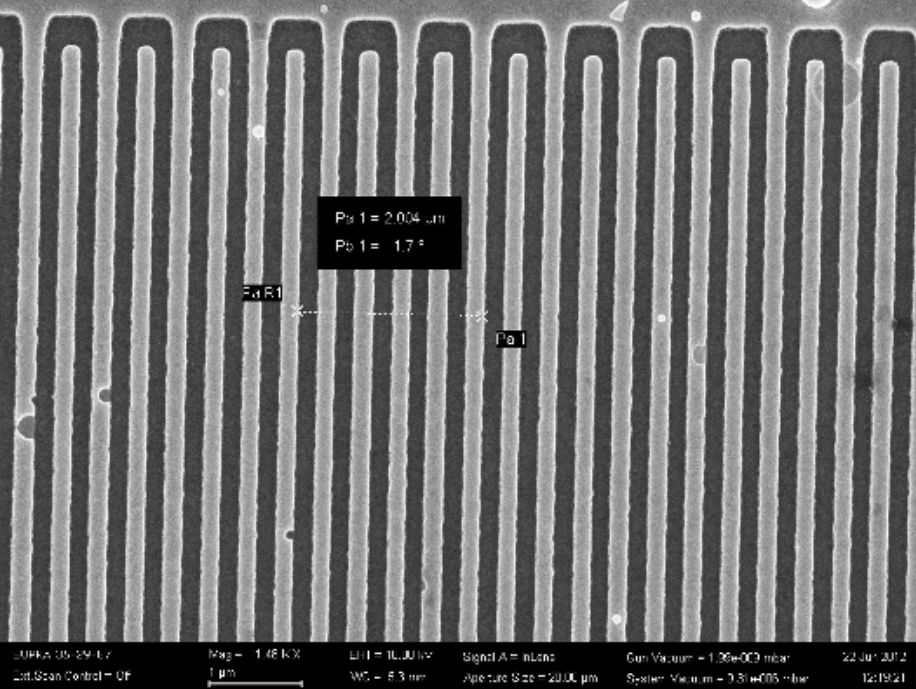

The new masks (run 4) have different single resonator SAW structures with IDTs having 200 nm, 170 nm and 150 nm wide finger/interdigit spacing. The structures have an interdigitated transducer with 150 fingers and 150 interdigits and 50 reflectors, placed on both sides of the IDT at different distances:

- 0.2 µm, 0.8 µm, 0.95 µm for 200 nm wide IDT fingers

- 0.15 µm, 0.6 µm, 0.7 µm for 150 nm wide IDT fingers

- 0.17 µm, 0.68 µm, 0.8 µm for 170 nm wide IDT fingers. .

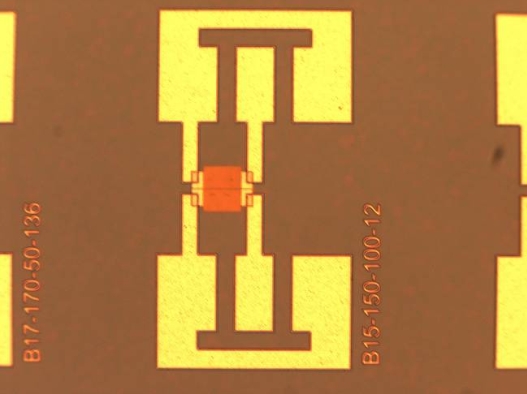

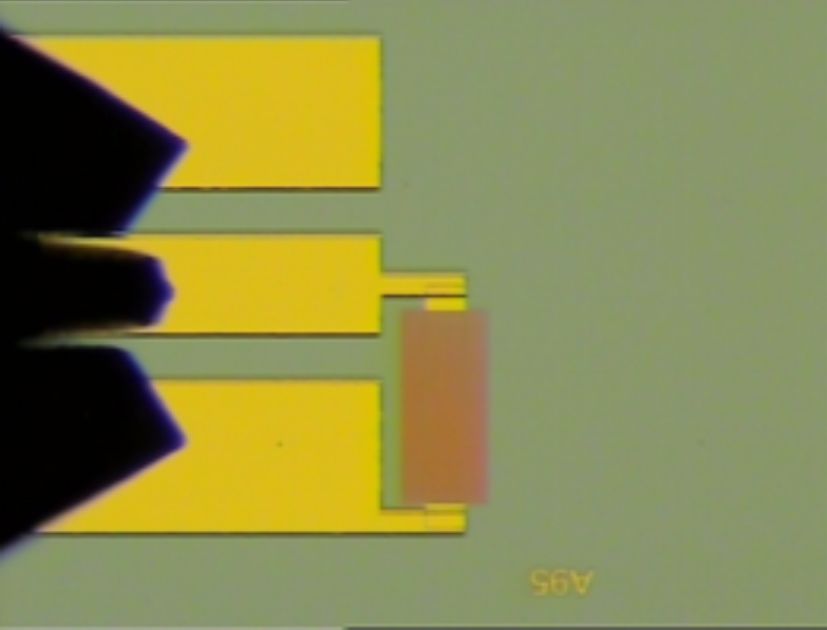

Optical photo(run4)

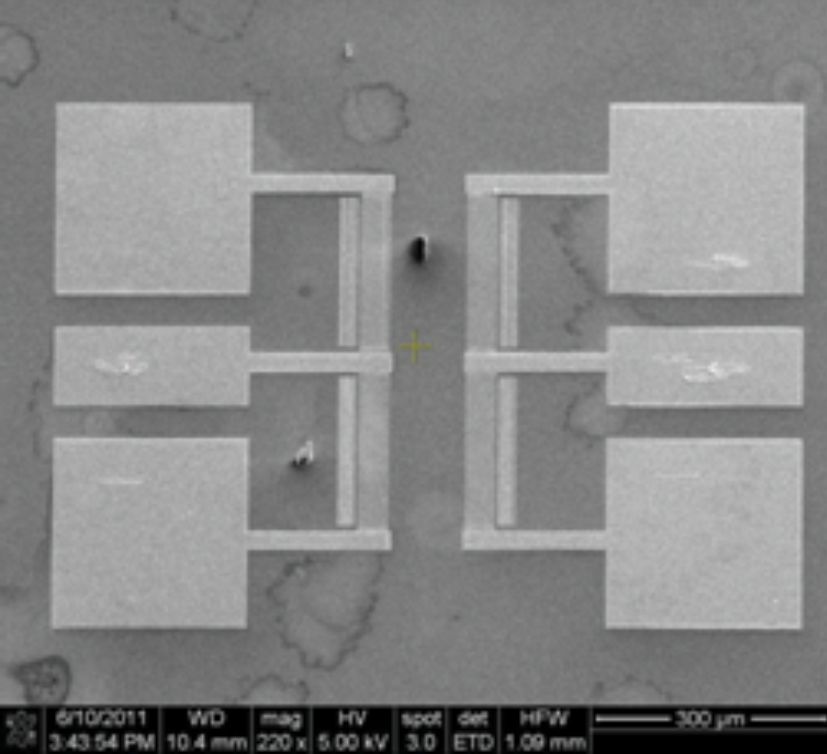

SEM image (run4)

-

Characterization of the SAW pemperature structure mounted on ceramic support.

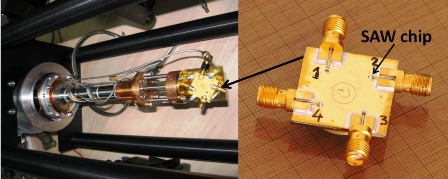

A cryostat (SHI-4H-1 from Janis Research company, LCC) able to perform in the 5-500K temperature range, available in IMT since beginning of March 2013, was used for device characterization

(a) (b)

Cryostat set-up available in IMT and (b) Diced chips assembled on special designed ceramic wafer

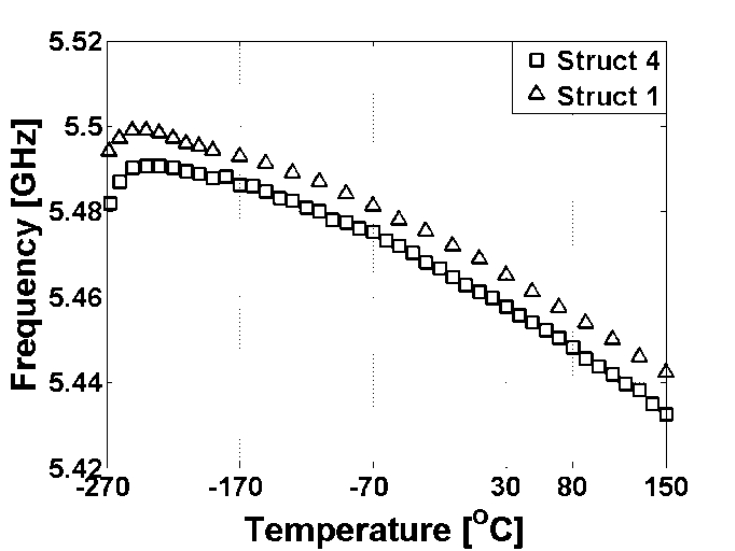

Resonance frequency vs temperature for SAW chips mounted on ceramic (run 2), obtained from S11 measurements from -268 oC to 150 oC

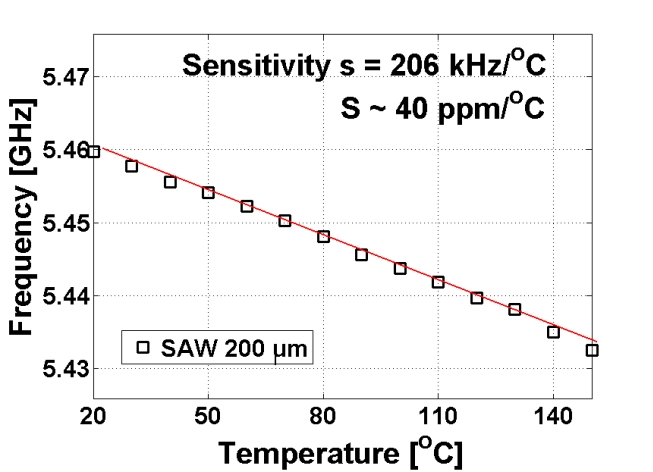

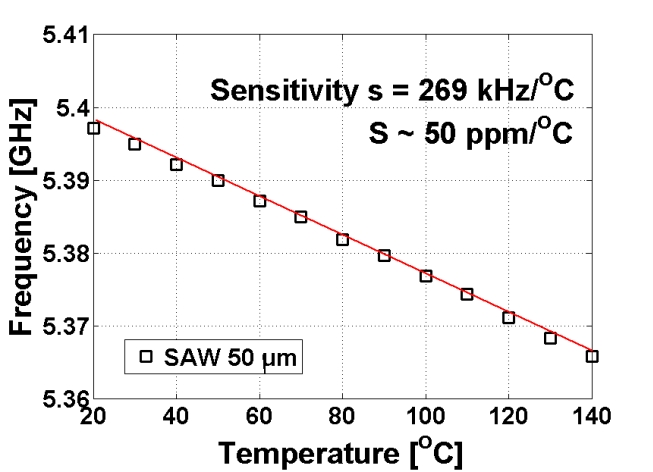

Resonance frequency vs temperature for SAW chips mounted on ceramic(run 2), obtained from S11 measurements from 20 oC to 150 oC

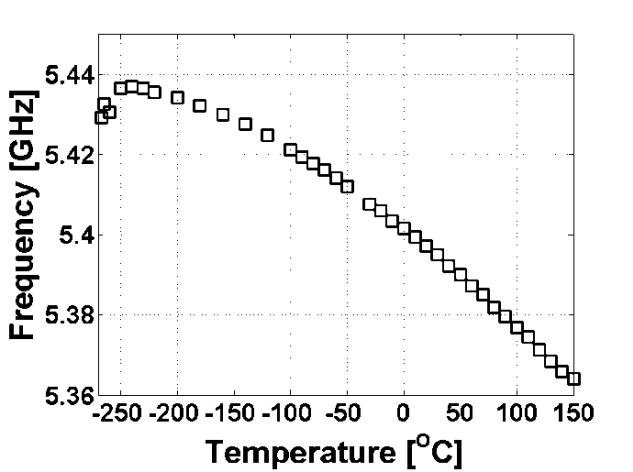

Resonance frequency vs temperature for SAW chips mounted on ceramic (run 3), obtained from S11 measurements from -250 oC to 150 oC

Resonance frequency vs temperature for SAW chips mounted on ceramic (run 3), obtained from S11 measurements from 20 oC to 150 oC

Scientific workshop organized at the IEEE conference CAS 2013

A scientific workshop of the project was organized by IMT during „International Semiconductor Conference CAS 2013” (IEEE event). Two of the presentation were from the Romanian team involved in the project.

Papers presented:

- A Muller, G Konstantinidis, A Dinescu, V Buiculescu, A Stefanescu, A cismaru, I Giangu, A Stavrinidis, T Kostopuolos – „GaN SAW based temperature sensors”

- Lilei Ye, Murali Murugesan, Johan Liu – “Carbon fiber-metal based composite for thermal interface material application”

- V Buiculescu, I. Giangu, A Stefanescu and A Muller– “Temperature measurement using SAW resonators embedded within RF wired systems”

- B. Wunderle, C.-A. Manier, M. Abo Ras, M. Springborn, D. May, H. Oppermann, M. Toepper, R. Mrossko, T. Xhonneux, T. Caroff, W. Maurer, R. Mitova - "Double-Sided Cooling and Thermo-Electrical Management of Power Transients for Silicon Chips on DCB-Substrates for Converter Applications: Design, Technology and Test"

Rezults 2012

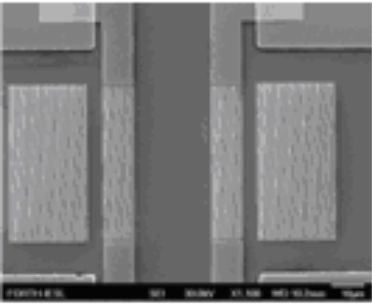

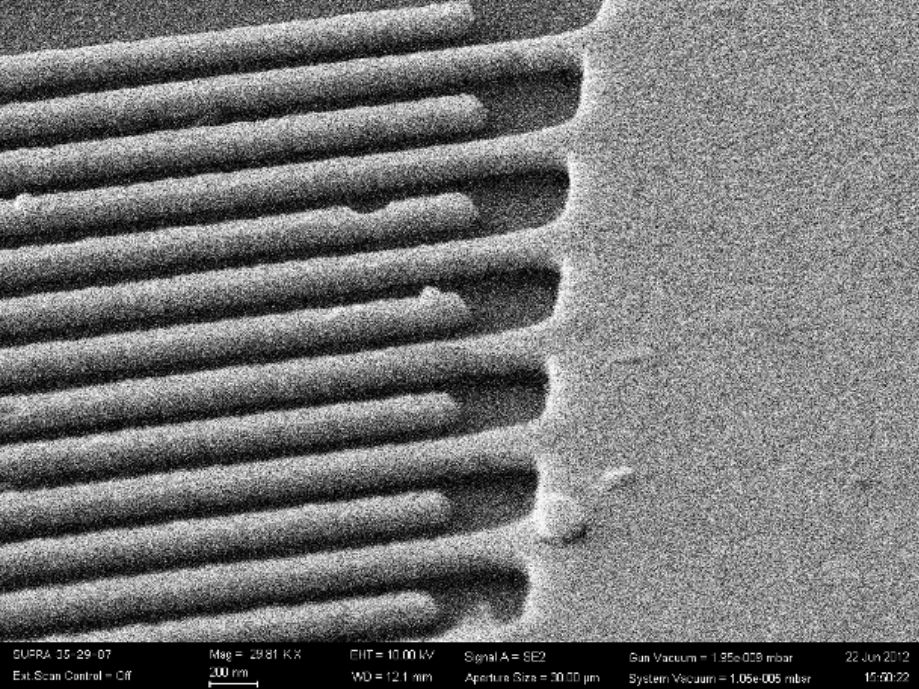

SAW/GaN structure and details with nanolithography of the 200 nm digits and interdigits

White light interferometry of the SAW structure

SAW on GaN structure fabrication and optimization for temperature sensor application

“Face-to-face” SAW structures have been obtained with 100 digits of 200µm length, 60 reflectors, digit/interdigit distance of 200 nm and 130 nm, respectively. TiAu of 100nm metallization and contacts metallization of 350nm have been used. S parameters has been measured by “on wafer” characterization.

SAW structure with IDT's of 100µm length, 0.2 µm width, distance between reflectors d= 0.95µm; Q = 320 (second run)

SEM images with details of nanolithographic GaN SAW structures

SAW devices characterization as temperature sensor in the range -65 ...+120 OC

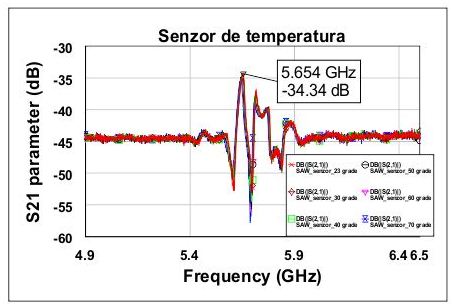

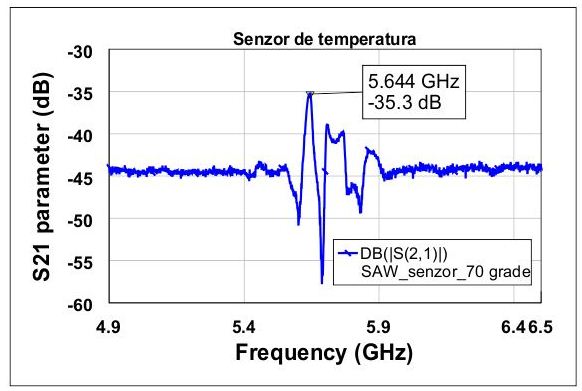

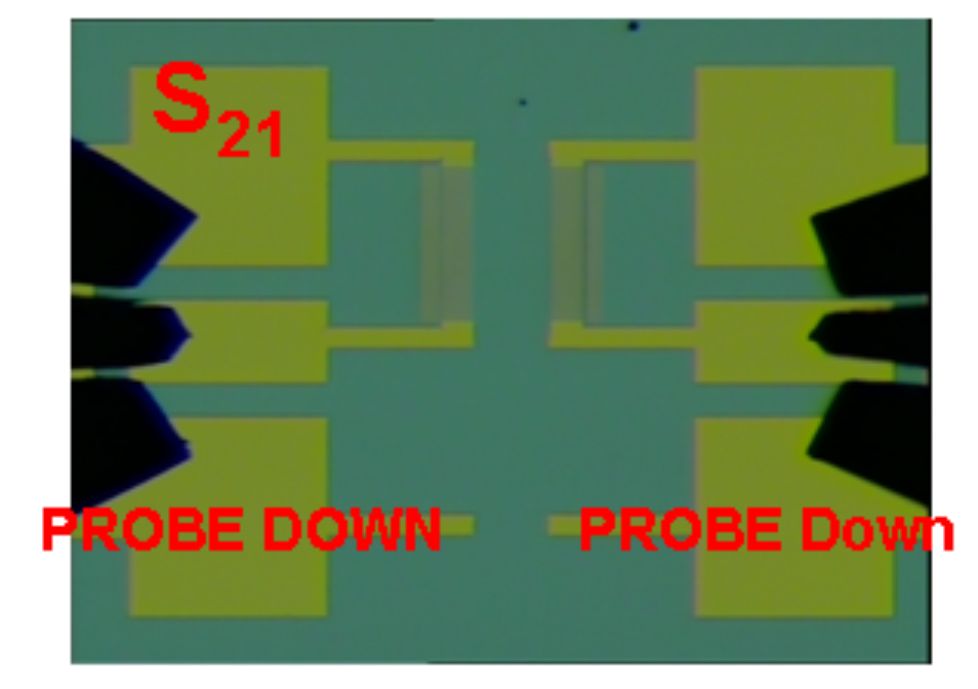

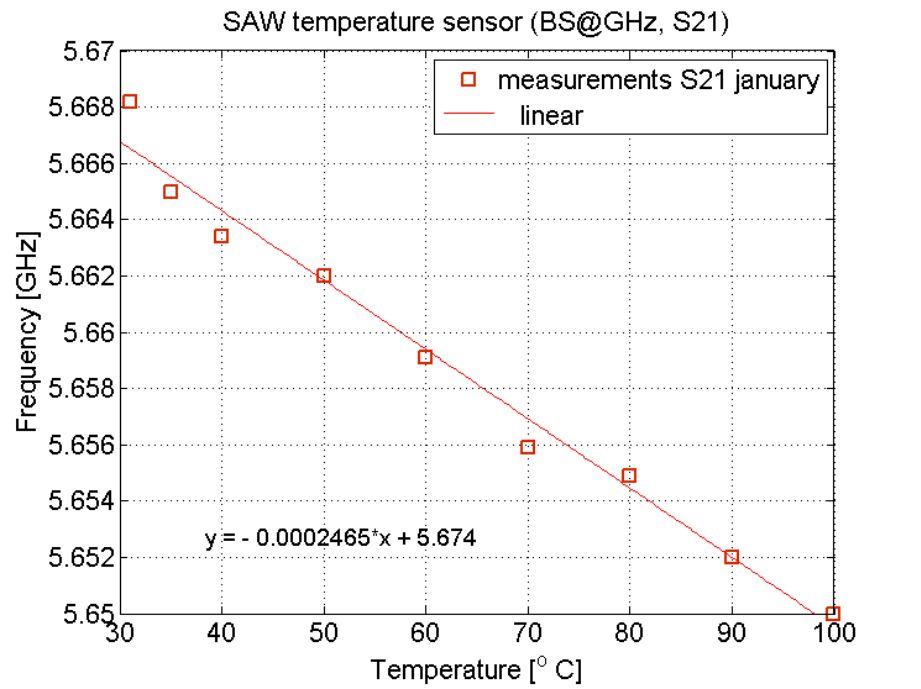

SAW structure and temperature dependence of rezonance frequency from S21

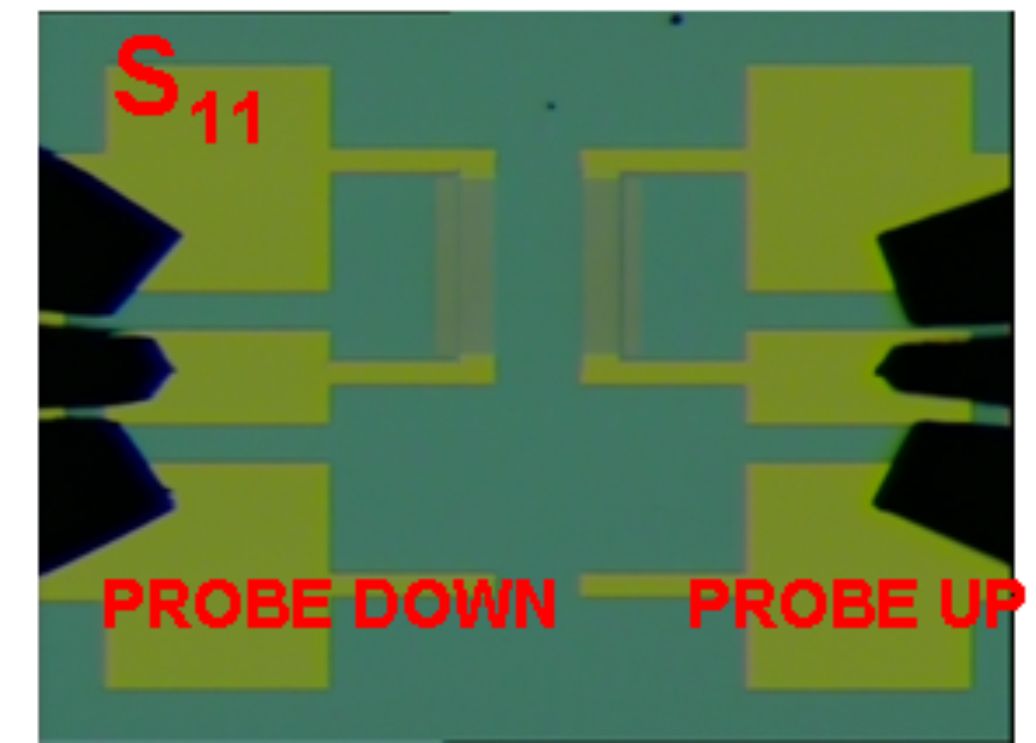

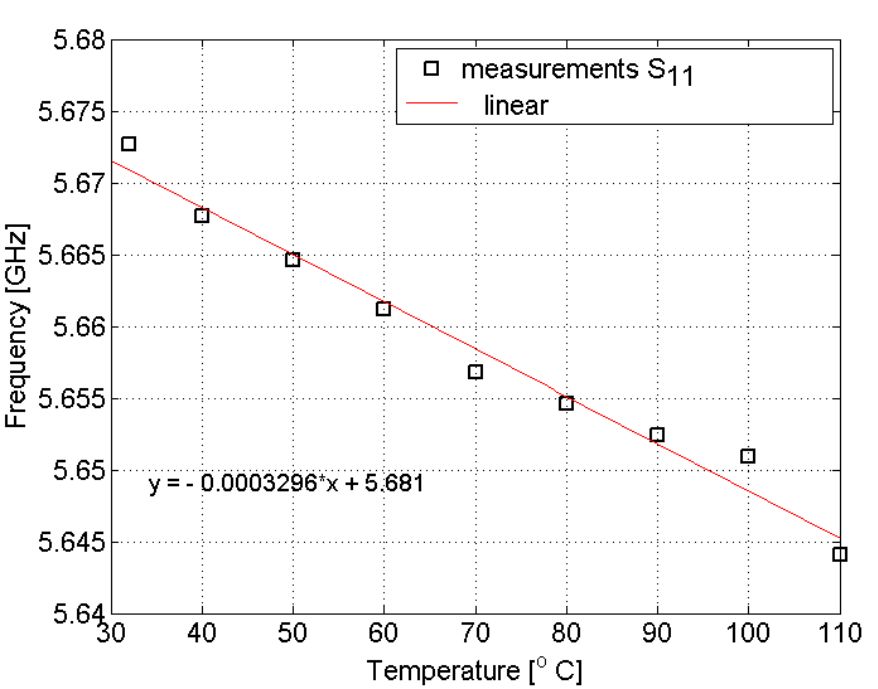

SAW structure and temperature dependence of rezonance frequency from S11

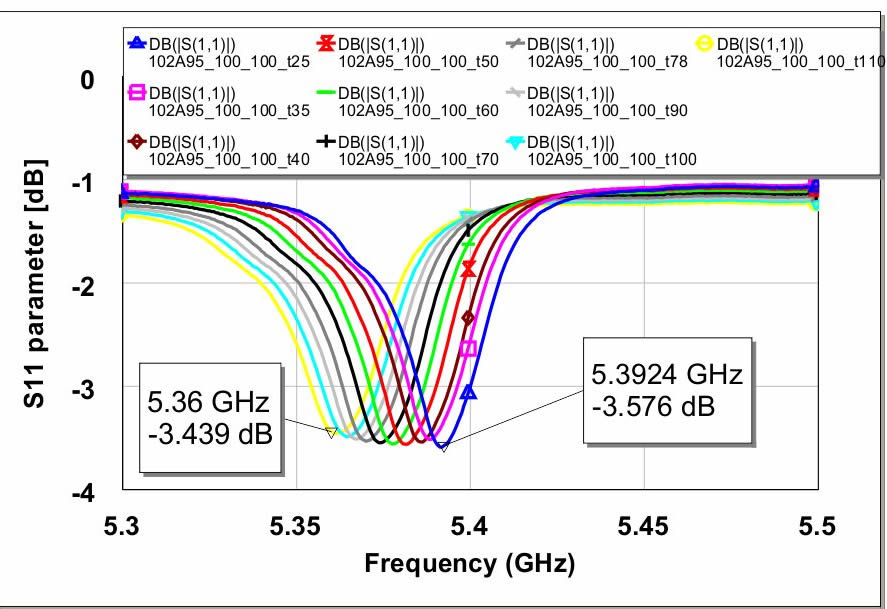

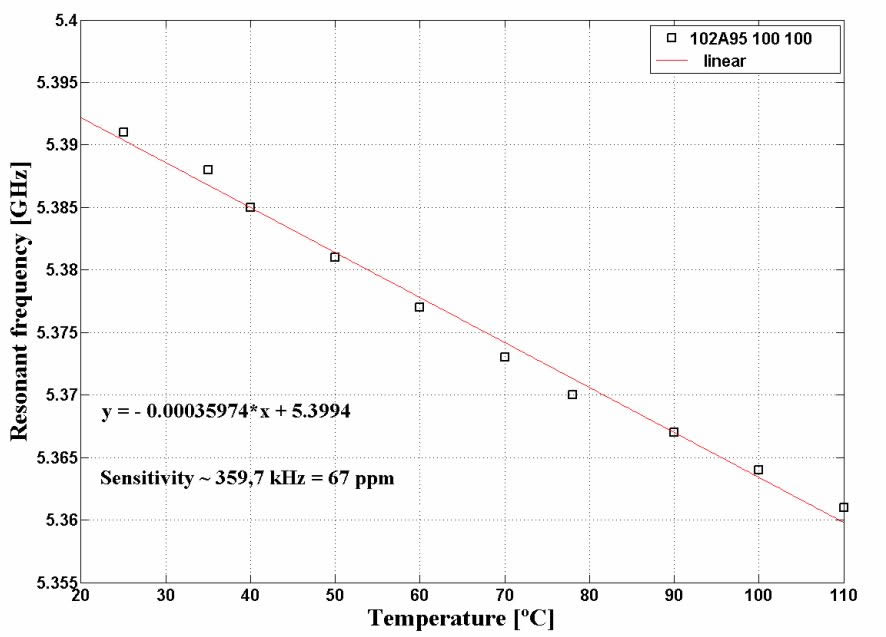

We present the temperature dependence of the resonance frequency obtained from S11 and “on wafer ” characterization for a SAW structure having IDT with 100 digits/interdigits and 100 µm length/digit

Temperature dependence of resonance frequency from S11 Sensitivity ~ 359.7 kHz/°C = 67 ppm /°C

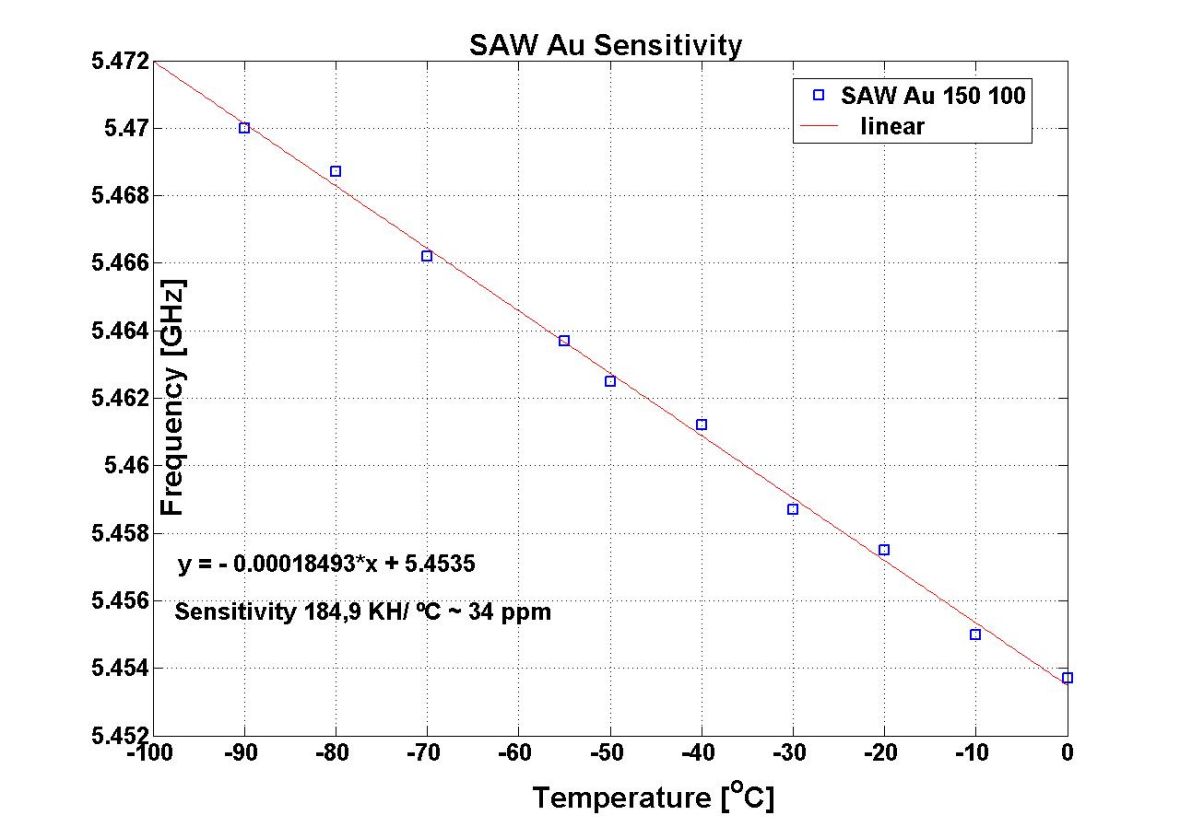

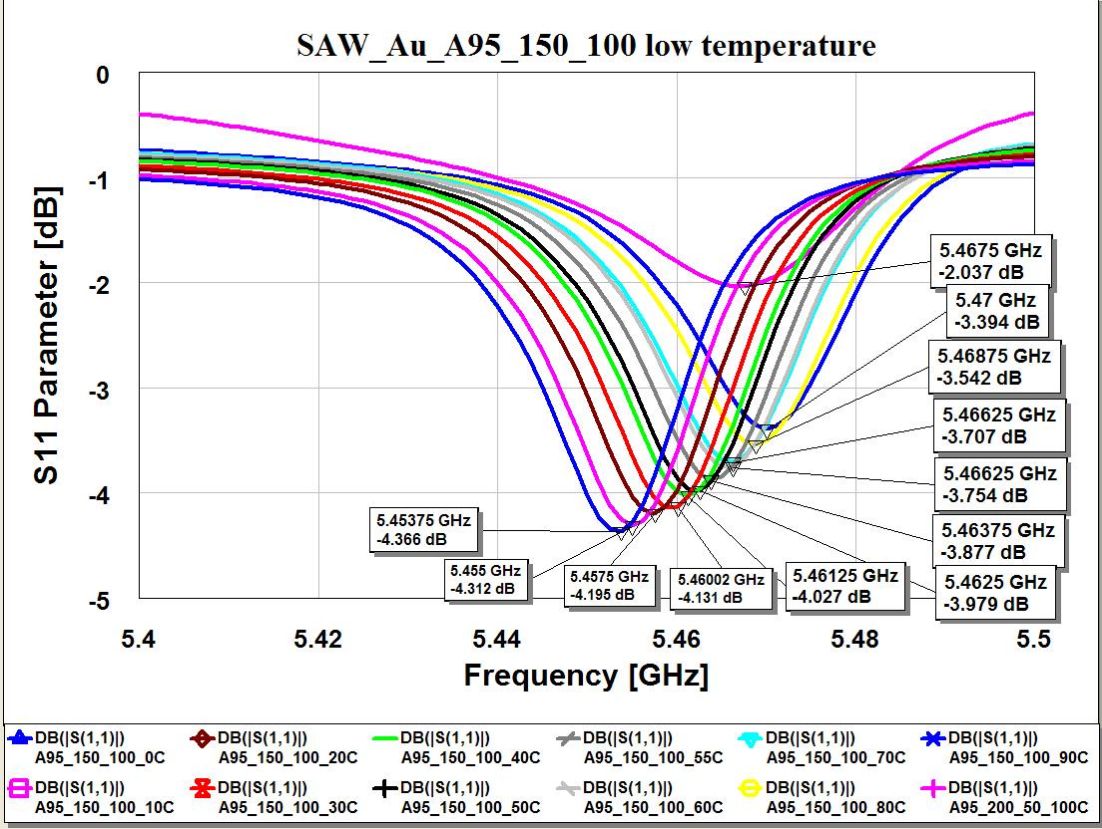

SAW structures with TiAu metallization, and Al metallization, having IDT with 150 digit’s of 100 µm length, have been tested at low temperatures, up to -100 OC. Rezuts are presented below.

“On wafer” characterization for SAW structure with TiAu metallization

Temperature dependence of resonance frequency for SAW structure with TiAu metallization